General engine overhaul procedures Ford F150

1. Included in Chapter are general information and diagnostic testing procedures for determining the overall mechanical condition of your engine.

2. The information ranges from advice concerning preparation for an overhaul and the purchase of replacement parts and/or components to detailed, step-by-step procedures covering removal and installation.

3. The following Sections have been written to help you determine whether your engine needs to be overhauled and how to remove and install it once you’ve determined it needs to be rebuilt. For information concerning in-vehicle engine repair, see V6 engines or V8 engines.

4. The Specifications included in this Part are general in nature and include only those necessary for testing the oil pressure and checking the engine compression, and bottom-end torque specifications. Refer to V6 engines or V8 engines for additional engine Specifications.

5. It’s not always easy to determine when, or if, an engine should be completely overhauled, because a number of factors must be considered.

6. High mileage is not necessarily an indication that an overhaul is needed, while low mileage doesn’t preclude the need for an overhaul. Frequency of servicing is probably the most important consideration. An engine that’s had regular and frequent oil and filter changes, as well as other required maintenance, will most likely give many thousands of miles of reliable service. Conversely, a neglected engine may require an overhaul very early in its service life.

7. Excessive oil consumption is an indication that piston rings, valve seals and/or valve

guides are in need of attention. Make sure that oil leaks aren’t responsible before deciding that the rings and/or guides are bad. Perform a cylinder compression check to determine the extent of the work required (see Cylinder compression check). Also check the vacuum readings under various conditions (see Vacuum gauge diagnostic checks).

8. Check the oil pressure with a gauge installed in place of the oil pressure sending unit and compare it to this Chapter’s Specifications (see Oil pressure check). If it’s extremely low, the bearings and/or oil pump are probably worn out.

9. Loss of power, rough running, knocking or metallic engine noises, excessive valve train noise and high fuel consumption rates may also point to the need for an overhaul, especially if they’re all present at the same time. If a complete tune-up doesn’t remedy the situation, major mechanical work is the only solution.

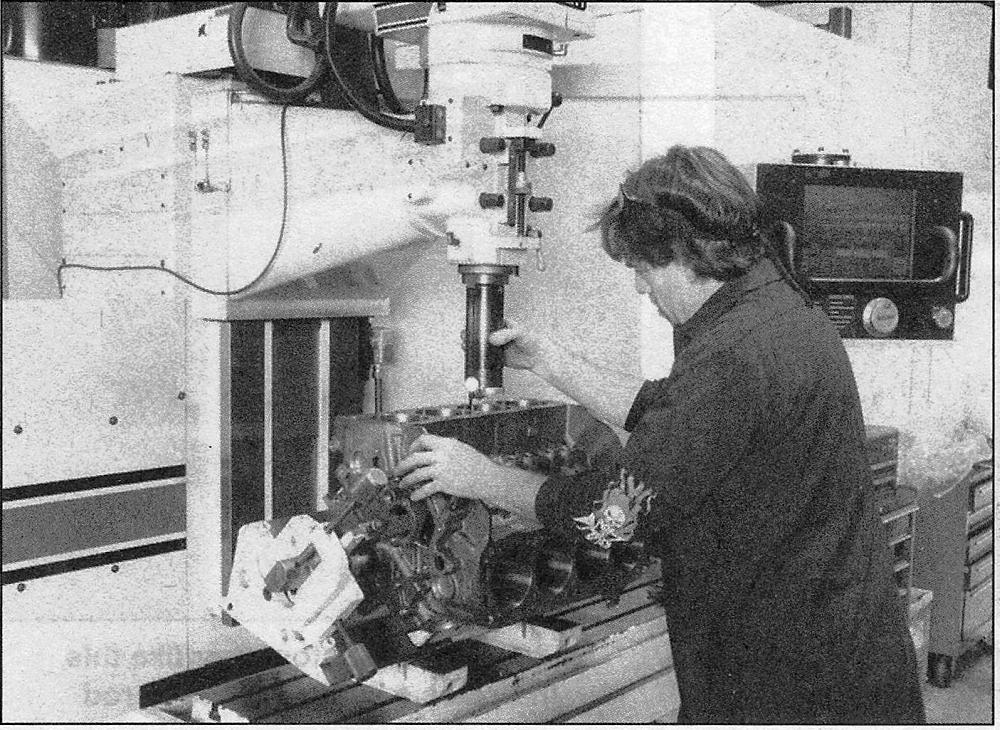

i.10 An engine block being bored. An engine rebuilder will use special machinery to recondition the cylinder bores

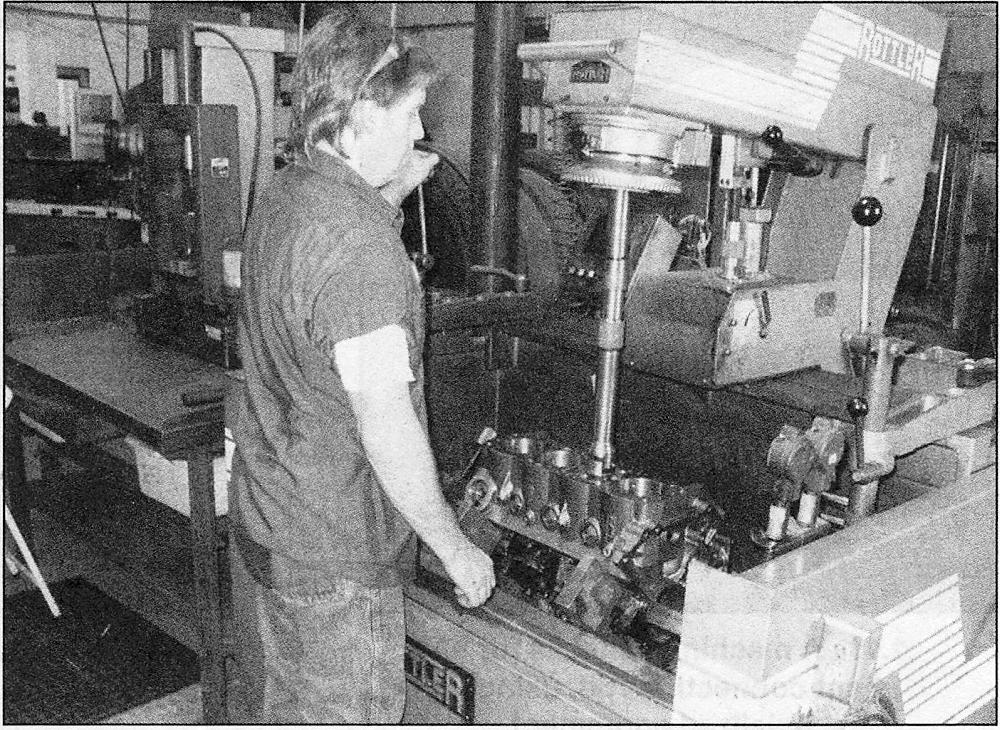

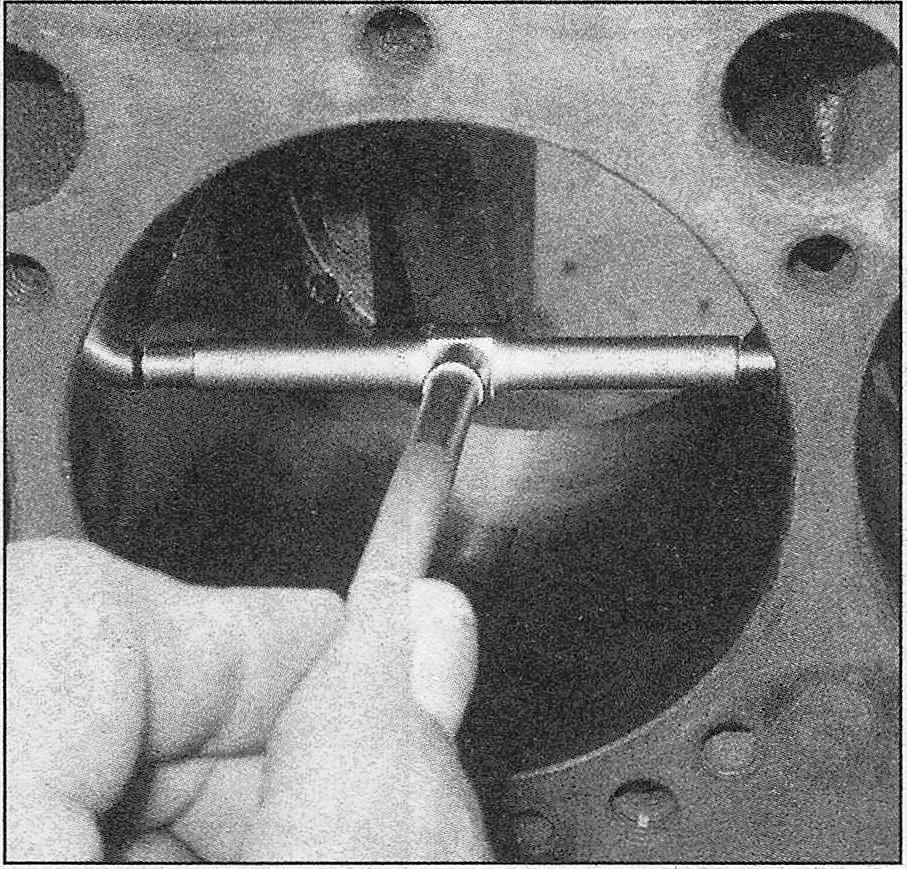

i.10b If the cylinders are bored, the machine shop will normally hone the engine on a machine like this

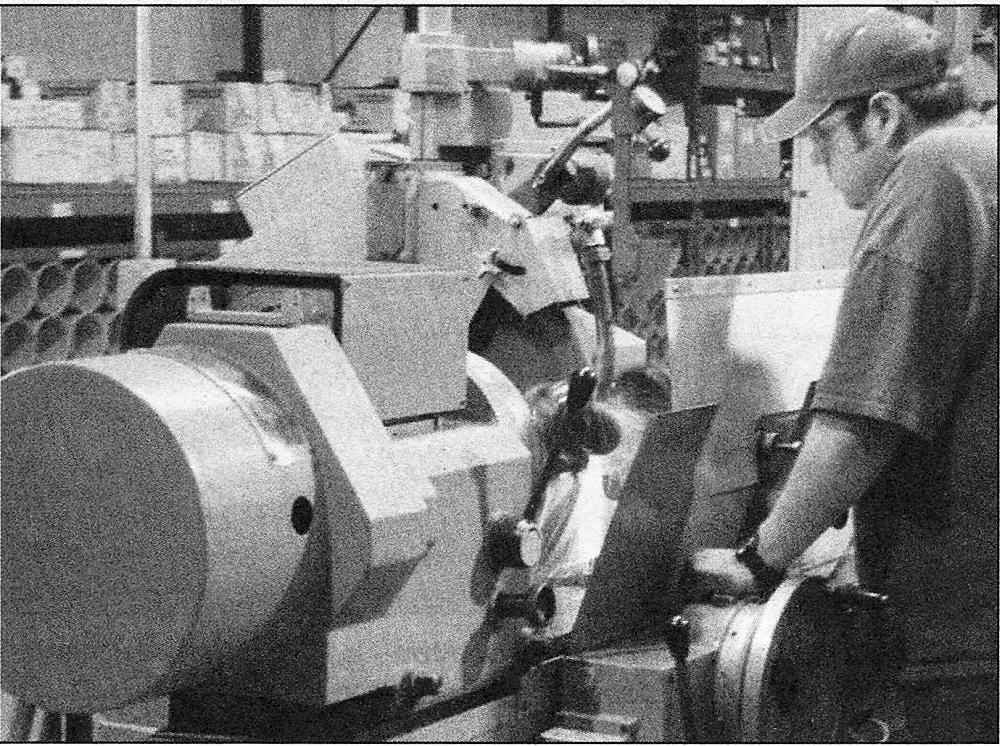

i.10c A crankshaft having a main bearing journal ground

10. An engine overhaul involves restoring the internal parts to the specifications of a new engine. During an overhaul, the piston rings are replaced and the cylinder walls are reconditioned (rebored and/or honed) (see illustrations 10a and 10b). If a rebore is done by an automotive machine shop, new oversize pistons will also be installed. The main bearings, connecting rod bearings and camshaft bearings are generally replaced with new ones and, if necessary, the crankshaft may be reground to restore the journals (see illustration 10c). Generally, the valves are serviced as well, since they’re usually in less-than-perfect condition at this point. While the engine is being overhauled, other components, such as the distributor, starter and alternator, can be rebuilt as well. The end result should be similar to a new engine that will give many trouble free miles.

Note: Critical cooling system components such as the hoses, drivebelts, thermostat and water pump should be replaced with new parts when an engine is overhauled. The radiator should be checked carefully to ensure that it isn’t clogged or leaking (see Tune-up and routine maintenance). If you purchase a rebuilt engine or short block, some rebuilders will not warranty their engines unless the radiator has been professionally flushed. Also, we don’t recommend overhauling the oil pump — always install a new one when an engine is rebuilt.

i.11a A machinist checks for a bent connecting rod, using specialized equipment

i.11b A bore gauge being used to check the main bearing bore

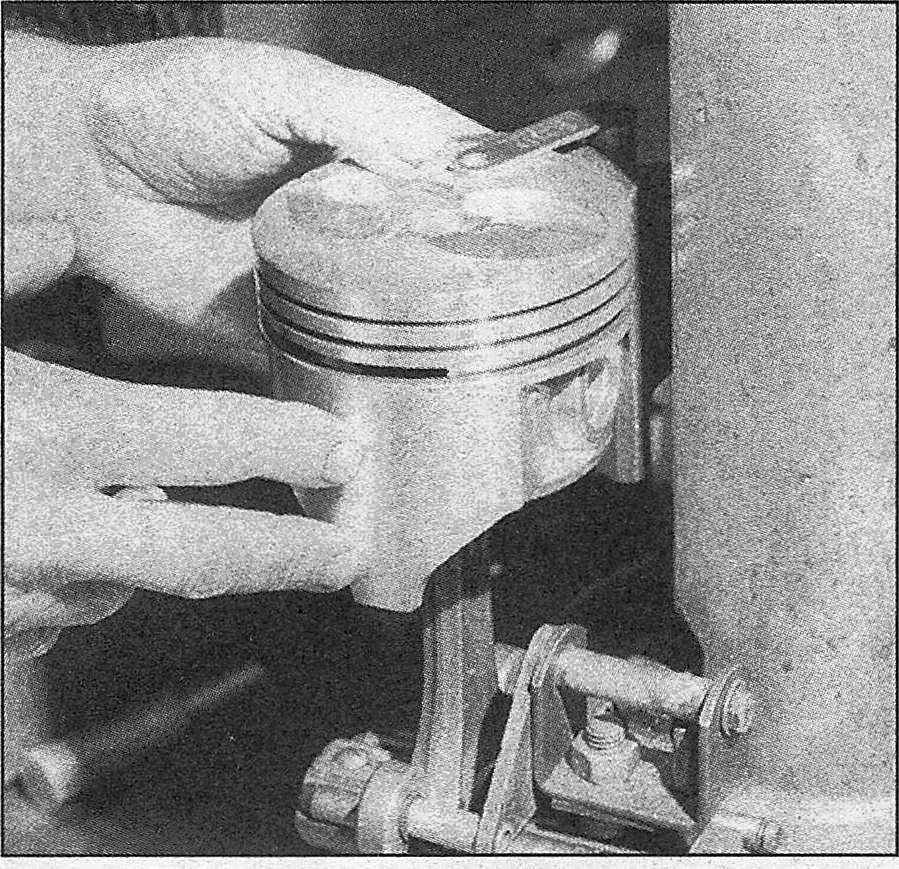

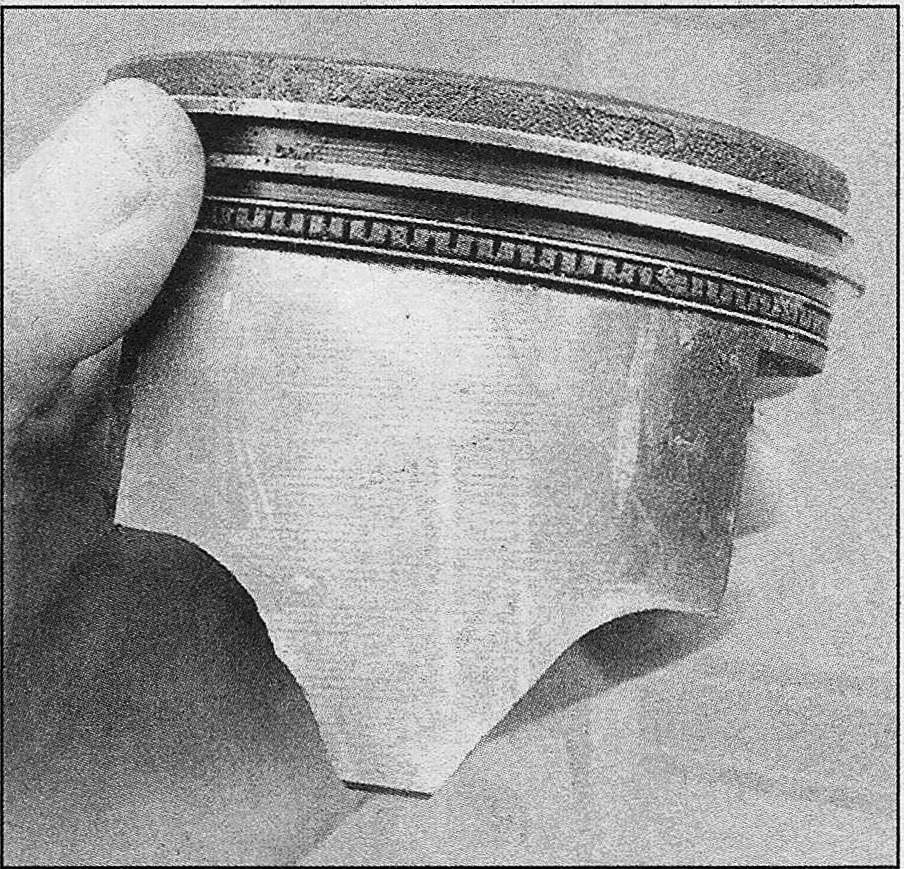

i.11c Uneven piston wear like this indicates a bent connecting rod

11. Overhauling the internal components on today’s engines is a difficult and time-consuming task which requires a significant amount of specialty tools and is best left to a professional engine rebuilder (see illustrations 11a, 11b and 11c). A competent engine rebuilder will handle the inspection of your old parts and offer advice concerning the reconditioning or replacement of the original engine, never purchase parts or have machine work done on other components until the block has been thoroughly inspected by a professional machine shop. As a general rule, time is the primary cost of an overhaul, especially since the vehicle may be tied up for a minimum of two weeks or more. Be aware that some engine builders only have the capability to rebuild the engine you bring them while other rebuilders have a large inventory of rebuilt exchange engines in stock. Also be aware that many machine shops could take as much as two weeks time to completely rebuild your engine depending on shop workload. Sometimes it makes more sense to simply exchange your engine for another engine that’s already rebuilt to save time.