Replace the spark plugs Ford F150

Tools required for changing spark plugs

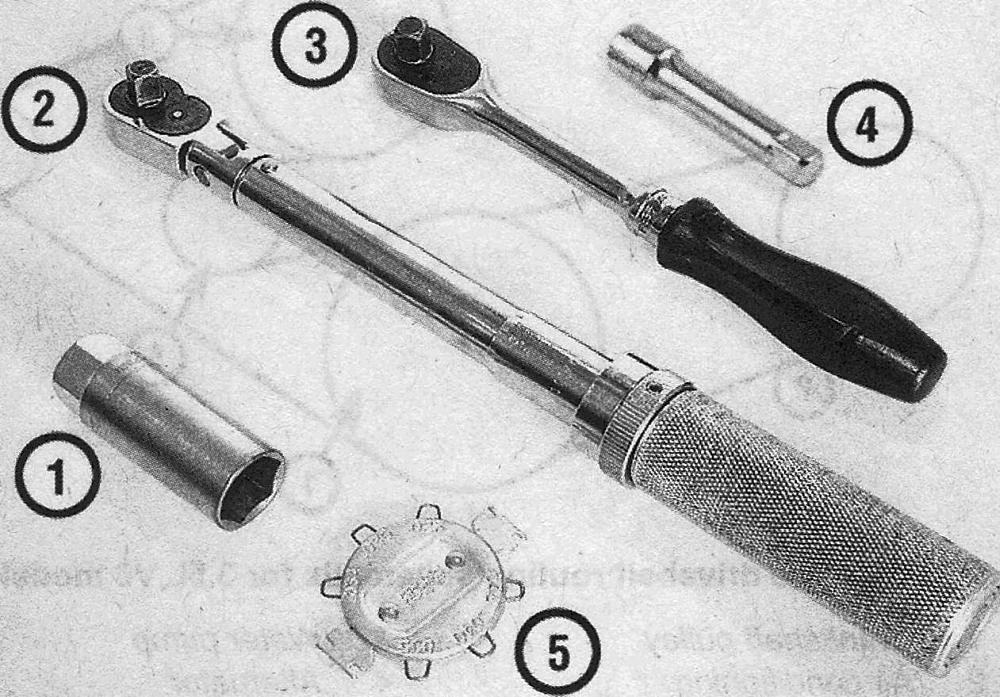

1. Spark plug socket — This will have special padding

inside to protect the spark plug’s porcelain insulator

2. Torque wrench — Although not mandatory, using this tool is the best way to ensure the plugs are tightened properly

3. Ratchet — Standard hand tool to fit the spark plug socket

4. Extension — Depending on model and accessories, you may need special extensions and universal joints to reach one or more of the plugs

5. Spark plug gap gauge — This gauge for checking the gap comes in a variety of styles. Make sure the gap for your engine is included

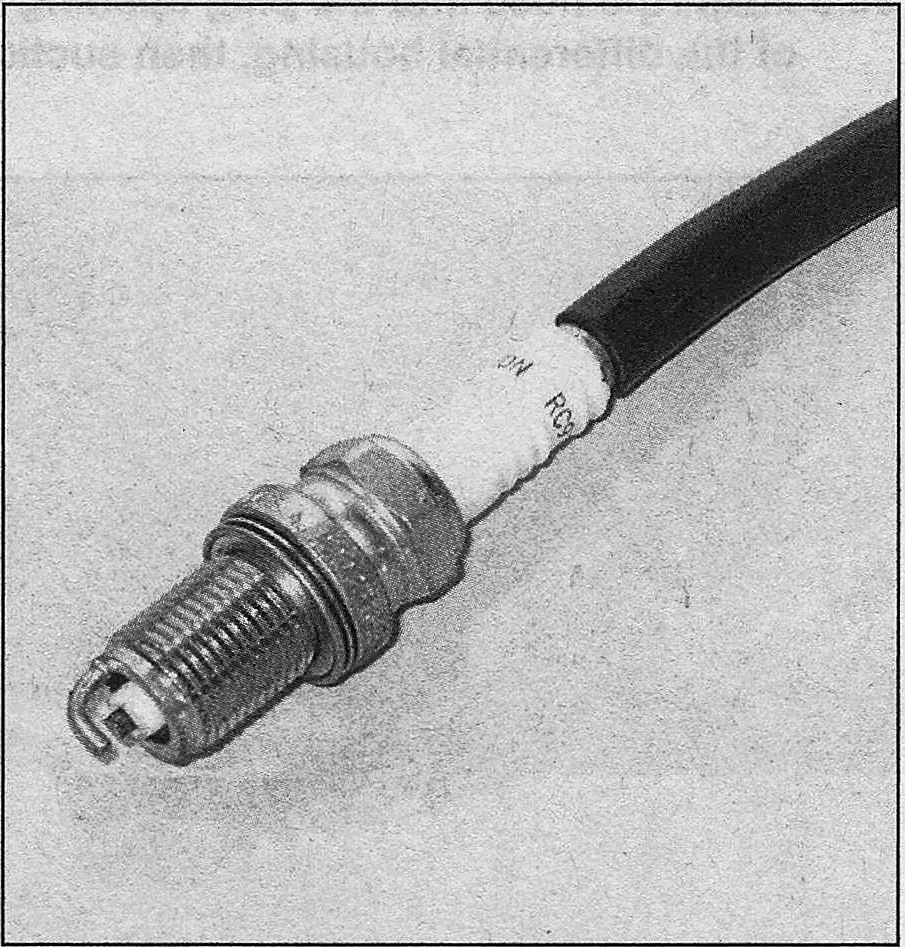

1. In most cases, the tools necessary for spark plug replacement include a spark plug socket which fits onto a ratchet (spark plug sockets are padded inside to prevent damage to the porcelain insulators on the new plugs), various extensions and a gap gauge to check and adjust the gaps on the new plugs (see illustration). A torque wrench should be used to tighten the new plugs.

2. The best approach when replacing the spark plugs is to purchase the new ones in advance, adjust them to the proper gap and replace the plugs one at a time. When buying the new spark plugs, be sure to obtain the correct plug type for your particular engine. This information can be found in this Chapter’s Specifications or in the owner’s manual.

3. Allow the engine to cool completely before attempting to remove any of the plugs. These engines are equipped with aluminum cylinder heads, which can be damaged if the spark plugs are removed when the engine is hot. While you are waiting for the engine to cool, check the new plugs for defects and adjust the gaps.

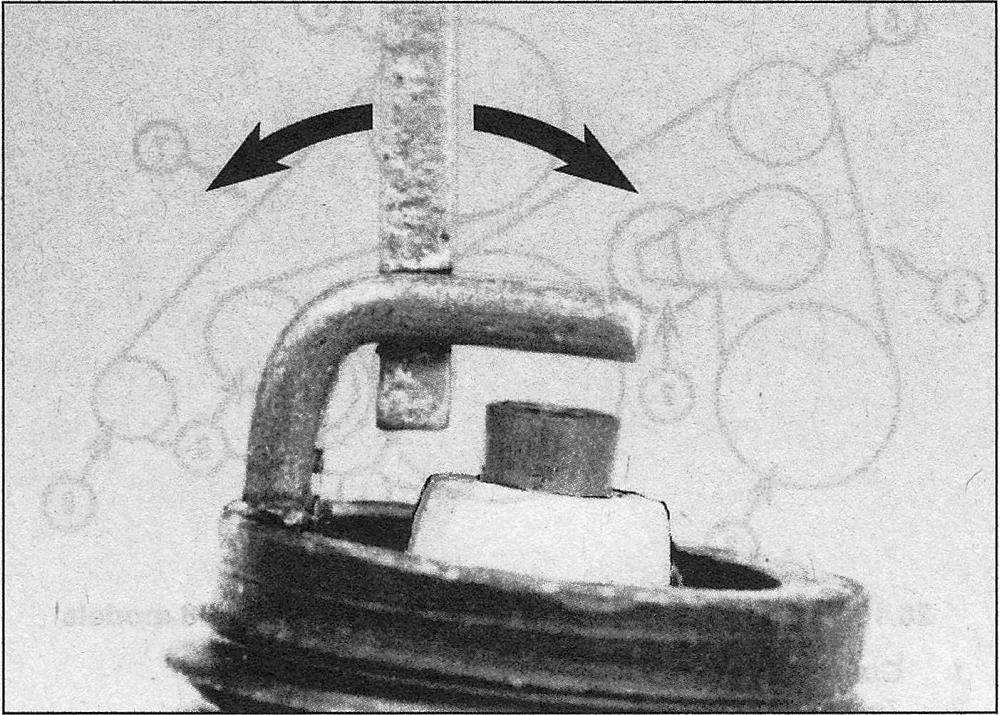

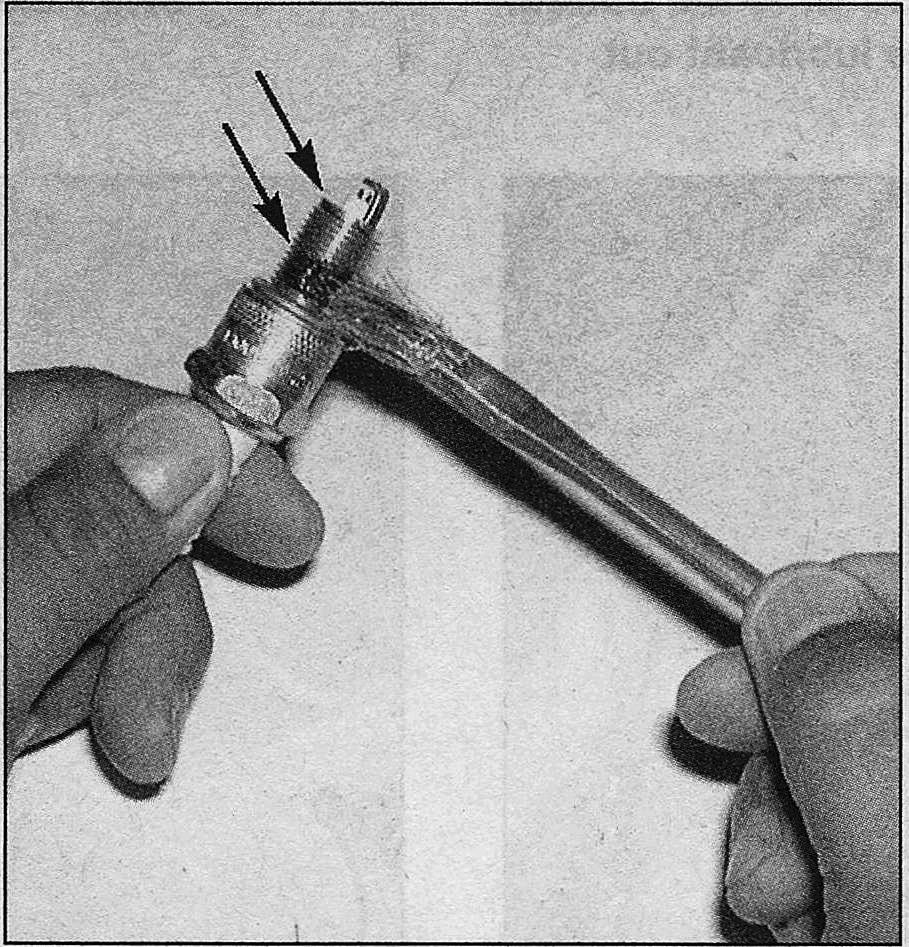

Spark plug manufacturers recommend using a wire-type gauge when checking the gap — if the wire does not slide between the electrodes with a slight drag, adjustment is required

To change the gap, bend the side electrode only, as indicated by the arrows, and be very careful not to crack or chip the porcelain insulator surrounding the center electrode

4. The gap is checked by inserting the proper thickness gauge between the electrodes at the tip of the plug. The gap between the electrodes should be the same as the one specified on the Emissions Control Information label. The wire should just slide between the electrodes with a slight amount of drag. If the gap is incorrect, use the adjuster on the gauge body to bend the curved side electrode slightly until the specified gap is obtained. If the side electrode is not exactly over the center electrode, bend it with the adjuster until it is. Check for cracks in the porcelain insulator (if any are found, the plug should not be used).

Caution: Some spark plug manufacturers recommend against checking and/or adjusting the gap on certain types of plugs — these plugs have been preset to a specified gap at the factory or contain a delicate layer of iridium that could be easily scraped off. Be sure to follow the directions provided with the plugs before checking/adjusting the gap.

Replacement

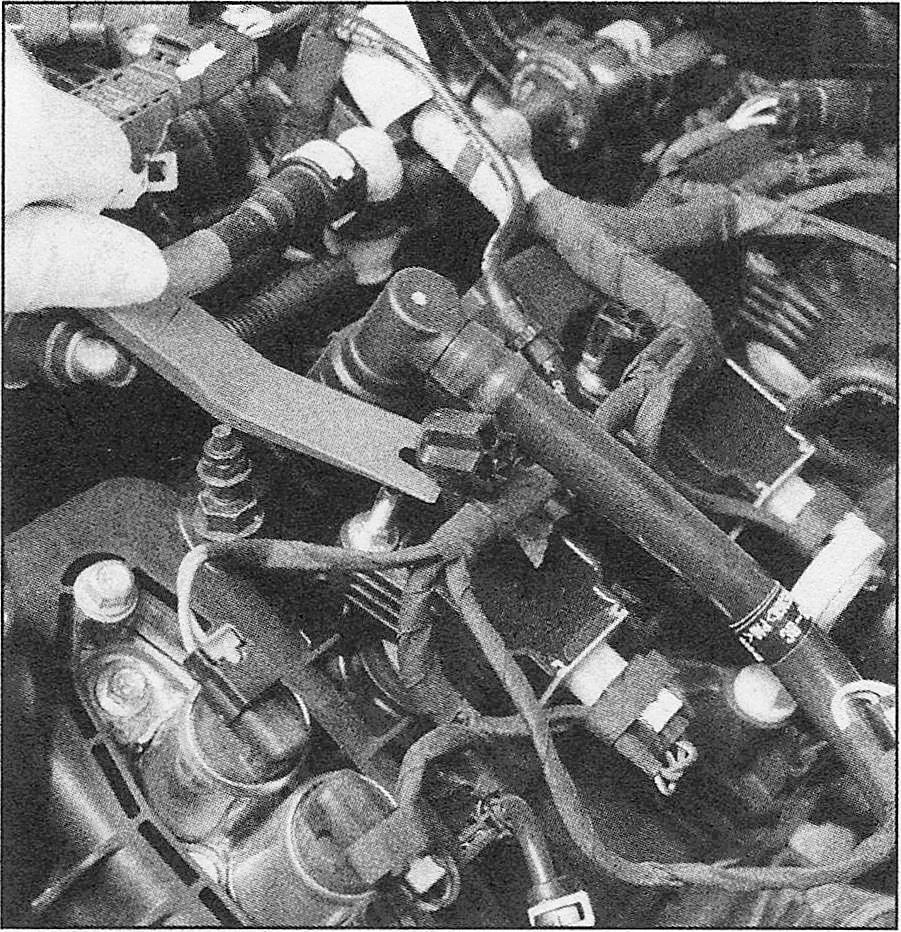

5. These models are equipped with individual ignition coils mounted on top of the spark plugs which must be removed to access the spark plugs.

Note: On 3.3L and 3.5L non-turbocharged V6 engines, the upper intake manifold must be removed to access the right-side ignition coils (see V6 engines).

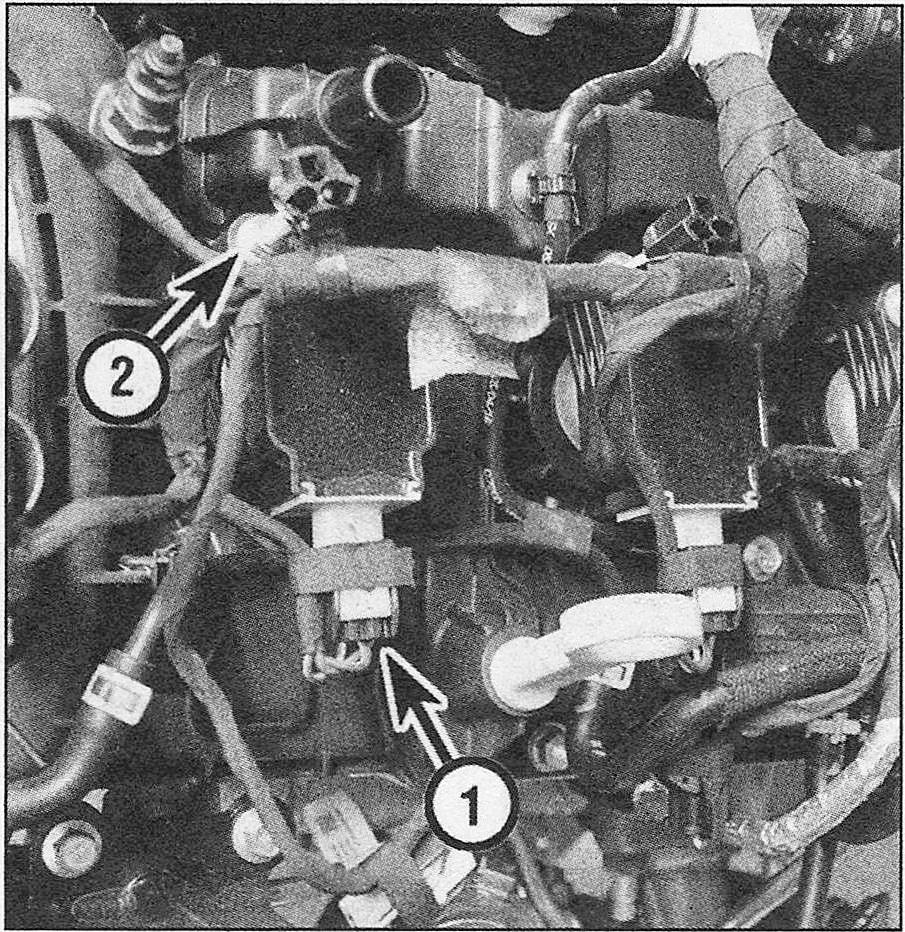

The ignition coils must be removed to access the spark plugs — disconnect the harness retaining clip from the stud bolt…

… then disconnect the electrical connector (1) and remove the coil retaining bolt (2)…

… pull straight up and out to remove the coil (2.7L V6 model shown — other models similar)

6. To remove the spark plugs, the individual ignition coils must be removed first to access the spark plugs.

7. If compressed air is available, use it to blow any dirt or foreign material away from the spark plug to eliminate the possibility of debris falling into the cylinder as the spark plug is removed.

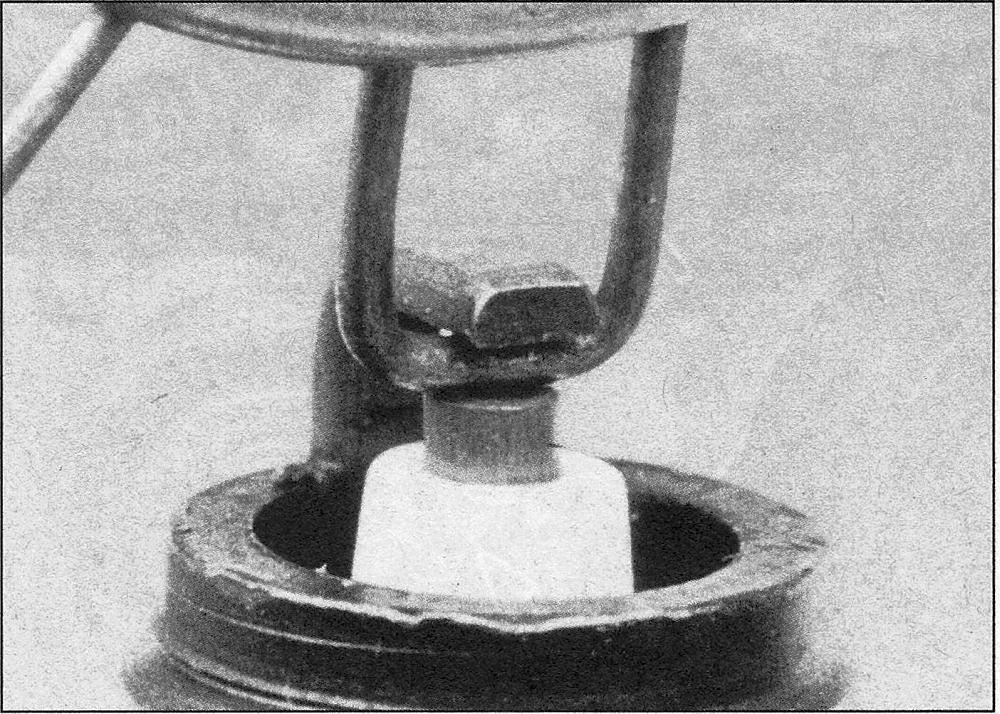

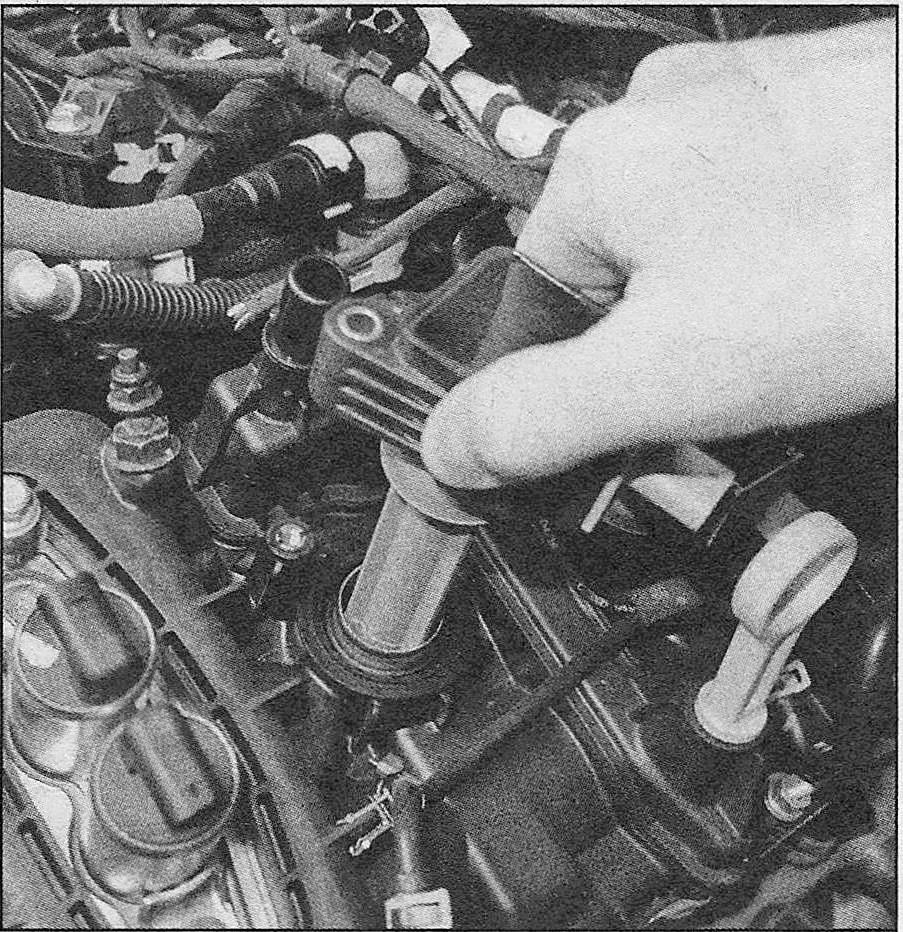

Use a ratchet and spark plug socket on an extension to remove the spark plugs

8. Place the spark plug socket with an extension over the plug and remove it from the engine by turning it in a counterclockwise direction.

9. Compare the spark plugs to those shown in the accompanying chart on the inside rear cover to get an indication of the general running condition of the engine.

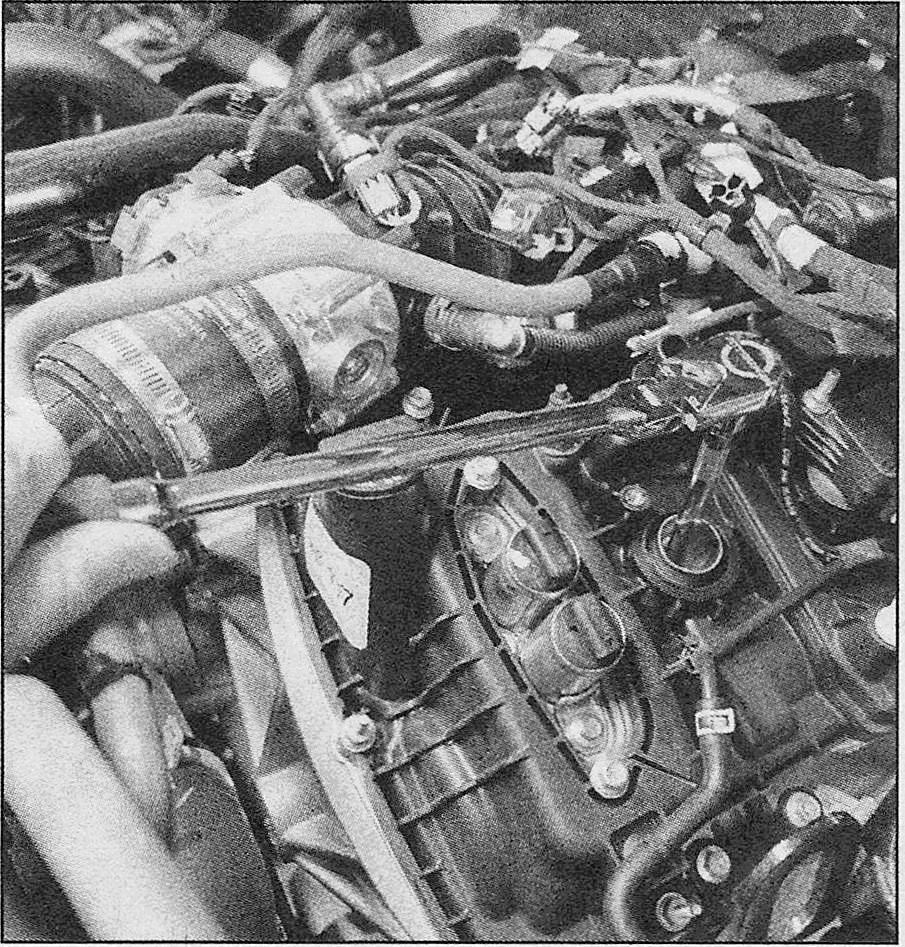

Apply a thin film of anti-seize compound to the spark plug threads

A length of rubber hose will save time and prevent damaged threads when installing the spark plugs

10. Apply a small amount of anti-seize compound to the spark plug threads. Install one of the new plugs into the hole until you can no longer turn it with your fingers, then tighten it with a torque wrench (if available) or the ratchet. It is a good idea to slip a short length of rubber hose over the end of the plug to use as a tool to thread it into place. The hose will grip the plug well enough to turn it, but will start to slip if the plug begins to cross-thread in the hole — this will prevent damaged threads and the accompanying repair costs.

11. Before pushing the ignition coil onto the end of the plug, inspect it following the procedures outlined in Inspect and replace, if necessary, the ignition coils.

12. Repeat the procedure for the remaining spark plugs. Installation is the reverse of removal.