Cylinder heads — removal and installation Ford F150

Warning: Wait until the engine is completely cool before beginning this procedure.

Removal

1. Relieve the fuel system pressure (see Fuel and exhaust systems), then disconnect the cable from the negative battery terminal (see Battery – disconnection and reconnection).

2. Drain the cooling system (see Tune-up and routine maintenance).

3. Remove the drivebelt and the drivebelt tensioner (see Tune-up and routine maintenance).

4. Remove the intake manifold(s) (see Intake manifold(s) – removal and installation).

5. On 3.3L and 3.5L models, remove the coolant crossover manifold bolts and crossover manifold.

6. Remove the exhaust manifold (see Exhaust manifolds – removal and installation).

7. Remove the turbocharger(s) (see Fuel and exhaust systems), if equipped.

8. On turbocharged models, disconnect the high-pressure fuel line(s) from the fuel rail and high-pressure fuel pump (see Fuel and exhaust systems).

Caution: The manufacturer requires the fuel line from the fuel rail to the high-pressure fuel pump always be replaced once it has been removed.

9. Remove the valve covers (see Valve covers – removal and installation).

10. Remove the front cover (see Engine front cover – removal and installation), timing chains and timing chain guides (see Section 10).

11. Remove the camshafts and tappets (see Camshafts and tappets/roller followers and lash adjusters – removal and installation).

12. On 3.3L and 3.5L engines, remove the two Camshaft Position (CMP) sensors at the rear of each cylinder head. On all models, disconnect any other electrical connectors from the cylinder head and mark them with tape for correct reassembly.

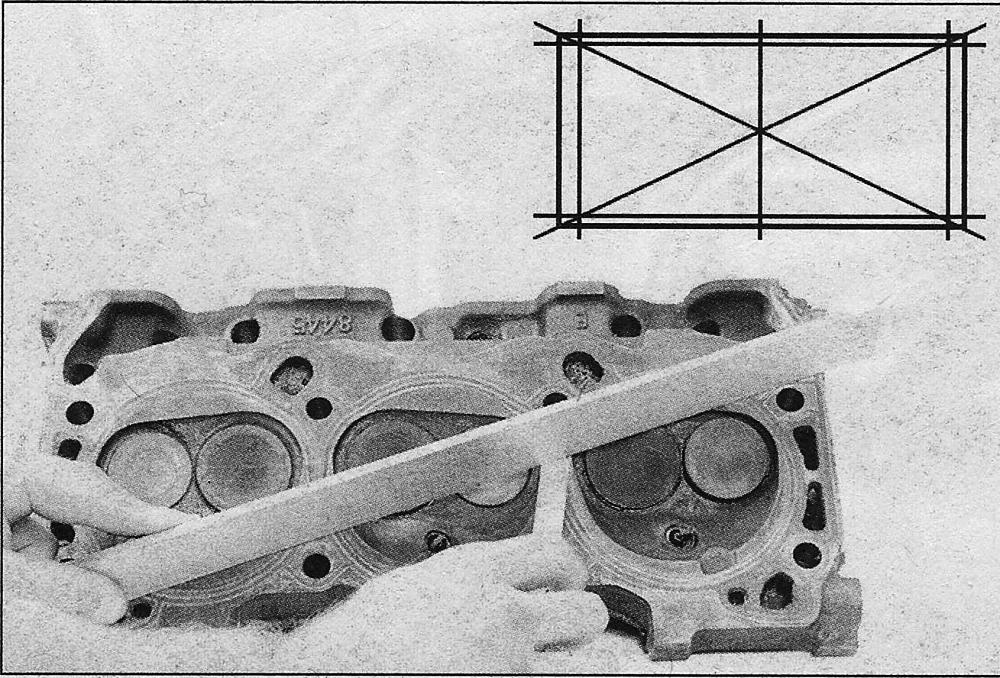

13. Loosen the cylinder head bolts in 1/4-turn increments until they can be removed by hand. Work from bolt-to-bolt in a pattern that’s the reverse of the tightening sequence (see illustration 22).

Caution: Remove the bolts and discard them — new bolts must be used when installing the cylinder head(s).

14. Lift the cylinder head(s) off the engine. If resistance is felt, DO NOT pry between the cylinder head and engine block as damage to the mating surfaces will result. To dislodge the cylinder head, place a wood block against the end of it and strike the wood block with a hammer or pry against a casting protrusion. Store the cylinder heads on blocks of wood to prevent damage to the gasket sealing surfaces.

15. Cylinder head disassembly and inspection procedures should be performed by a qualified automotive machine shop.

Installation

16. The mating surfaces of the cylinder heads and engine block must be perfectly clean when the cylinder heads are installed. Caution: Do not use a scraper of any kind or abrasive discs to remove old gasket material, as the block, heads and intake manifold(s) are aluminum (except for on the 2.7L engine; the block is constructed of compacted graphite iron, but care should still be taken). Cover all openings with shop rags to keep debris out of the engine. Use a vacuum cleaner to remove any debris that falls into the valley or intake ports.

Check the cylinder head and block surfaces for flatness with a straightedge

17. Check the engine block and cylinder head mating surfaces for nicks, deep scratches and other damage. If damage is slight, it can be removed with a file — if it’s excessive, machining may be the only alternative. Use a straightedge and feeler gauges to check for warpage. If the warpage is beyond Specifications, have the head machined at an automotive machine shop.

18. Use a tap of the correct size to chase the threads in the block head bolt holes. Dirt, corrosion, sealant and damaged threads will affect torque readings.

19. Position the new gasket(s) over the dowel pins in the engine block. Make sure it’s facing the right way. If the cylinder head is to be replaced, a new secondary timing chain tensioner will be required.

20. Carefully position the cylinder head(s) on the engine block without disturbing the gasket(s).

21. Before installing the new cylinder head bolts, lightly oil the threads.

Cylinder head bolt tightening sequence — 2.7L engine

Cylinder head bolt tightening sequence — 3.3L and 3.5L engines

22. Install the bolts and tighten them finger-tight. Tighten the bolts, in the recommended sequence, to the torque listed in this Chapter’s Specifications.

23. On 3.3L and 3.5L engines, install and tighten the M6 bolt at the front of the cylinder head to the torque listed in this Chapter’s Specifications.

24. The remaining installation steps are the reverse of removal.

25. Change the engine oil and filter and refill the cooling system (see Tune-up and routine maintenance), then start the engine and check carefully for oil and coolant leaks.