Valve clearance — check and adjustment Ford F150

Valve clearance (3.3L Duratec, 3.5L Duratec and 2016 and earlier 3.5L EcoBoost engines) — check and adjustment.

Note: The engine must be room temperature before checking the valve clearances.

Note: Checking and, if necessary, adjusting the valve clearance is only necessary after replacement of the camshaft(s) or other valve-related parts, or if the valvetrain is making excessive noise.

1. Disconnect the cable from the negative terminal of the battery (see Engine electrical systems).

2. Remove the spark plugs (see Tune-up and routine maintenance).

3. Remove the valve covers (see Valve covers – removal and installation).

4. Using a socket and a breaker bar on the crankshaft pulley center bolt, rotate the engine until the cam lobes on the cylinder to be checked are pointing away from the tappets.

Measure the clearance for each valve with a feeler gauge of the specified thickness — if the clearance is correct, you should feel a slight drag on the gauge as you pull it out

5. Measure the clearance of the indicated valves with a feeler gauge. Record each measurement and compare your measurements with the desired valve clearance found in this Chapter’s Specifications. Note which are out of specification, as this data will be used later to determine the required replacement tappets.

6. Repeat Steps 4 and 5 until the clearances for all valves have been measured.

7. If a clearance is out of specification, the tappet must be replaced with a new tappet that has a different thickness head to correct the clearance. Refer to Camshafts and tappets/roller followers and lash adjusters – removal and installation and remove the camshafts to access the tappets.

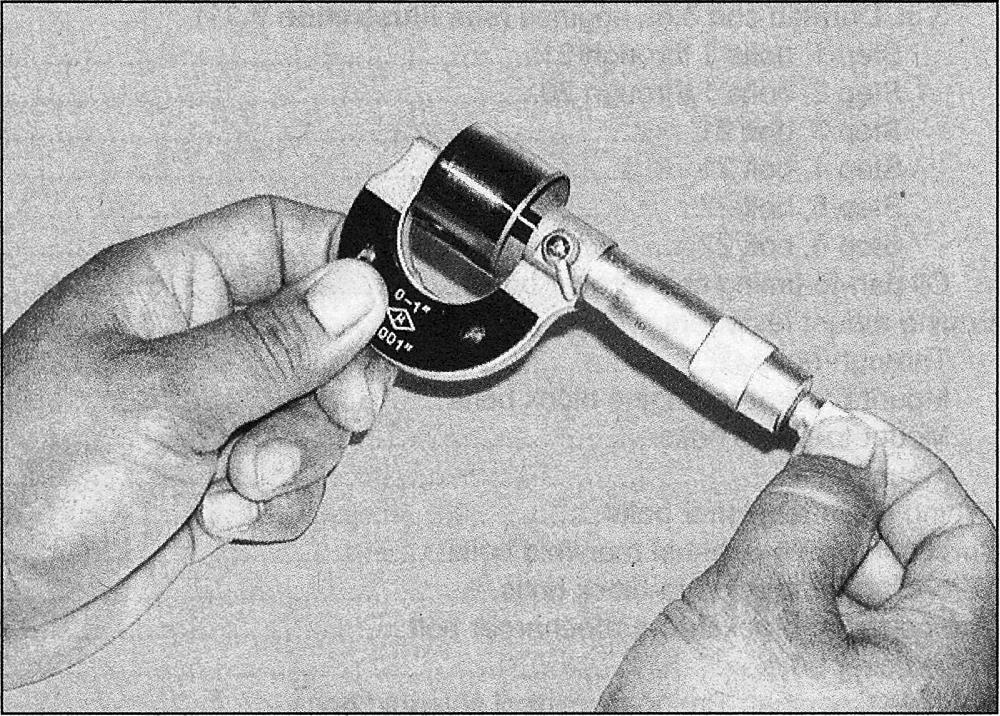

Use a micrometer to measure the thickness of the head of the tappet

8. Mark the lifters that are to be replaced, and record which valve they came from. Use a micrometer to measure the thickness of the head of the lifter, making sure the measurement is precise and on the center projection on the underside of the lifter.

9. To calculate the correct thickness for a replacement lifter that will place the valve clearance within the specified value, use the following formula:

N = R + (M1 — M2)

N = thickness of new tappet

R = measured valve clearance

M1 = thickness of old tappet

M2 = standard valve clearance

10. Lifters are marked on the underside as to their size. A marking of 3.310 on the underside of the lifter indicates a thickness value of 3.31 mm, or 0.13 inch.

11. Mark the new lifters as to their destination, lubricate them with engine assembly lube and install them. After replacing the lifters, refer to Camshafts and tappets/roller followers and lash adjusters – removal and installation to reinstall the camshafts and Section 10 to reinstall the timing chains, then re-check the valve clearances.