Emissions and engine control systems Ford F150

1. To prevent pollution of the atmosphere from incompletely burned and evaporating gases, and to maintain good driveability and fuel economy, a number of emission control systems are incorporated.

They include the:

- On-Board Diagnostic (OBD) II system

- Electronic Fuel Injection (EFI) system

- Evaporative Emissions Control (EVAP) system

- Positive Crankcase Ventilation (PCV) system

- Catalytic converter(s)

2. Before assuming that an emissions control system is malfunctioning, check the fuel and ignition systems carefully. The diagnosis of some emission control devices requires specialized tools, equipment and training. If checking and servicing become too difficult or if a procedure is beyond your ability, consult a dealer service department or other repair shop. Remember, the most frequent cause of emissions problems is simply a loose or broken wire or vacuum hose, so always check the hose and wiring connections first.

3. This doesn’t mean, however, that emissions control systems are particularly difficult to maintain and repair. You can quickly and easily perform many checks and do most of the regular maintenance at home with common tune-up and hand tools.

Note: Because of a Federally mandated warranty which covers the emissions control system components, check with your dealer about warranty coverage before working on any emissions-related systems. Once the warranty has expired, you may wish to perform some of the component checks and/or replacement procedures in this Chapter to save money.

4. Pay close attention to any special precautions outlined in this Chapter. It should be noted that the illustrations of the various systems may not exactly match the system installed on your vehicle because of changes made by the manufacturer during production or from year-to-year.

5. A Vehicle Emissions Control Information (VECI) label is attached to the underside of the hood. This label contains information regarding the types of emsissions control systems installed on the vehicle. When servicing the engine or emissions systems, the VECI label on your particular vehicle should always be checked for up-to-date information.

On Board Diagnosis (OBD) system

Obtaining and clearing Diagnostic Trouble Codes (DTCs)

Powertrain Control Module (PCM) – removal and installation

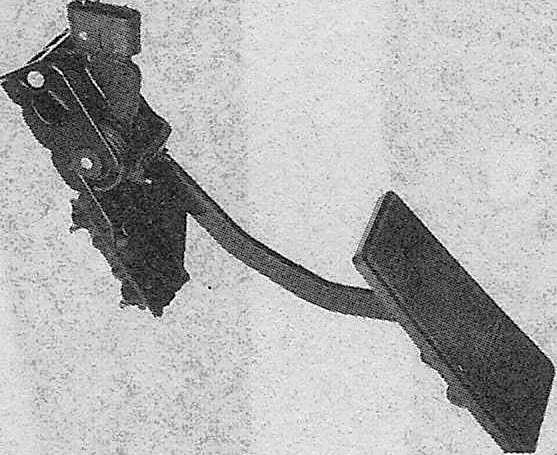

Accelerator Pedal Position (APP) sensor – replacement

Engine Coolant Temperature (ECT) sensor – replacement

Intake Air Temperature (IAT) sensor – replacement

Manifold Absolute Pressure (MAP) sensor – replacement

Cylinder Head Temperature (CHT) sensor – replacement

Crankshaft Position (CKP) sensor – replacement

Camshaft Position (CMP) sensor – replacement

Engine Oil Pressure (EOP) sensor – replacement

Oil pressure control solenoid – replacement

Variable Camshaft Timing (VCT) variable force solenoid – removal and installation

Turbocharger Boost Pressure (TCBP) and Charge Air Cooler Temperature (CACT) sensor – replacement

Turbocharger bypass valve – replacement

Turbocharger wastegate vacuum sensor – replacement

Oxygen sensors – general information and replacement

Knock sensors – replacement

Fuel tank pressure (FTP) sensor – replacement

Fuel rail pressure/temperature sensor – replacement

Positive Crankcase Ventilation (PCV) system

Evaporative emissions control (EVAP) system – general description and component replacement

Catalytic converter

Accelerator Pedal Position (APP) sensor — as you press the accelerator pedal, the APP sensor alters its voltage signal to the PCM in proportion to the angle of the pedal, and the PCM commands a motor inside the throttle body to open or close the throttle plate accordingly

Camshaft Position (CMP) sensor — produces a signal that the PCM uses to identify the number 1 cylinder and to time the firing sequence of the fuel injectors

Crankshaft Position (CKP) sensor — produces a signal that the PCM uses to calculate engine speed and crankshaft position, which enables it to synchronize ignition timing with fuel injector timing, and to detect misfires

Engine Coolant Temperature (ECT) sensor — a thermistor (temperature-sensitive variable resistor) that sends a voltage signal to the PCM, which uses this data to determine the temperature of the engine coolant

Fuel tank pressure sensor -measures the fuel tank pressure and controls fuel tank pressure by signaling the EVAP system to purge the fuel tank vapors when the pressure becomes excessive

Intake Air Temperature (IAT) sensor — monitors the temperature of the air entering the engine and sends a signal to the PCM to determine injector pulse-width (the duration of each injector’s on-time) and to adjust spark timing (to prevent spark knock)

Knock sensor — a piezoelectric crystal that oscillates in proportion to engine vibration which produces a voltage output that is monitored by the PCM. This retards the ignition timing when the oscillation exceeds a certain threshold

Manifold Absolute Pressure (MAP) sensor — monitors the pressure or vacuum inside the intake manifold. The PCM uses this data to determine engine load so that it can alter the ignition advance and fuel enrichment

Mass Air Flow (MAF) sensor -measures the amount of intake air drawn into the engine. It uses a hot-wire sensing element to measure the amount of air entering the engine

Oxygen sensors — generates a small variable voltage signal in proportion to the difference between the oxygen content in the exhaust stream and the oxygen content in the ambient air. The PCM uses this information to maintain the proper air/fuel ratio. A second oxygen sensor monitors the efficiency of the catalytic converter

Throttle Position (TP) sensor -a potentiometer that generates a voltage signal that varies in relation to the opening angle of the throttle plate inside the throttle body. Works with the PCM and other sensors to calculate injector pulse width (the duration of each injector’s on-time)